Electronic temperature controllers ERT

Why heating cotroller is needed? DH usually can not provide comfort in a heated room for any outside air temperature. Typically, there is underheating at low temperatures (-10º...-20ºC) and overheating at high (+5º...+15ºC). Underheating is usually compensated by electric heaters, and overheating - by opening the windows. Obviously, in both cases energy is partly wasted.

Comfortable temperature in the heated room can be achieved by changing the coolant flow depending on the outside air temperature. That is, at low outdoor air temperatures consumption should increase, at high – heat consumption drops. Practice shows that temperature in the return pipeline is a reliable indicator of a comfortable room temperature. Keeping it in accordance with the schedule of DH usually ensures comfort in heated rooms.

Heat controller solves two problems at once:

- provides comfort for inhabitants;

- allows to avoid overrun of heat in warm weather, and, consequently, significantly reduces the cost of heating.

Additional consumption savings and heat savings can be achieved for non-residential facilities by programming a small decrease in temperature in the return pipeline at night and on weekends or any other period programmed by the user. Algorithm mentioned above can be implemented using a simple controller, which includes an electronic control unit, outside air and return pipeline thermometer and governor valve Globe valve with electromechanical control by Swiss company BELIMO is used as the executing unit in controller.

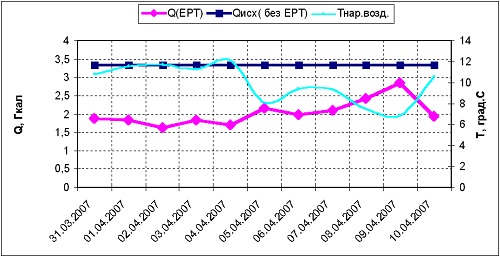

For example, let's consider heating thermocontroller ERT installed in 9 - storeyed 162-apartment building in Kyiv. before controller was installed the coolant flow rate was 176 tons per day, temperatures of coolant and reverse pipeline were respectively 59 and 40 C degrees. Hence (59-40) * 175.85 / 1000 = 3.34 Gcal per day were spent on heating the building. After thermocontroller was installed coolant temperature remained the same (59 deg. C), reverse flow temperature dropped to 29-33 C , coolant flow rate decreased to 52-110 tons per day. Accordingly, amount of thermal energy consumed for heating the building decreased making 1,70-2,85 Gcal per day depending on outside air temperature.

This example is illustrated by the graph of the amount of heat spent on heating the bulding, with and without controller, due time period . Also the graph of outside air temperature is shown.

According to the data listed in the table, it is easy to calculate heat energy savings and, consequently, financial savings due to the operation of thermoregulator during period from 03/31/07 to 04/10/07, i.e. 11 days of operation.

Date |

Q(ERT) |

Q(without ERT) |

T outdoor |

|

Gkal |

Gkal |

°С |

31.03.2007 |

1.88 |

3.34 |

10.84 |

01.04.2007 |

1.84 |

3.34 |

11.63 |

02.04.2007 |

1.64 |

3.34 |

11.77 |

03.04.2007 |

1.84 |

3.34 |

11.29 |

04.04.2007 |

1.7 |

3.34 |

12.13 |

05.04.2007 |

2.16 |

3.34 |

8.16 |

06.04.2007 |

1.99 |

3.34 |

9.43 |

07.04.2007 |

2.09 |

3.34 |

9.37 |

08.04.2007 |

2.43 |

3.34 |

7.51 |

09.04.2007 |

2.85 |

3.34 |

6.89 |

10.04.2007 |

1.94 |

3.34 |

10.58 |

Total |

22.36 |

36.74 |

|

Heat costs, UAH |

4583.8 |

7531.7 |

|

Economy, UAH |

2947.9 |

|

|

It is worth mentioning that thermocontroller provides the greatest savings in the offseason, as it becomes possible to make the coolant flow less than is arranged by heating system.